The copy of users.kpi.kharkov.ua/LaserLab/Faucet.html (existed up to Sept. 2021), with modified CONTACTS

&

SO,

Requested by NineSigma RFP #50526-1 - Liner/Coating Technology for Faucet Spouts REQUEST FOR PROPOSAL DESCRIPTION NineSigma, representing Multi-Billion Dollar Consumer Products Company, invites proposals for materials and process technologies to deposit a liner on the inside of brass faucet spouts. Successful liner technologies will meet the following criteria: ° Deposits a liner on the inside surface of the brass water channels of

faucet spouts Note: NineSigma's client seeks both liner materials and processes to deposit liners inside brass spouts BACKGROUND NineSigma's client is a worldwide leader in manufacturing consumer products and innovative plumbing fixtures for kitchens and bathrooms. Recent legislation has reduced the maximum allowable lead content used in materials that contact drinking water, such as brass. The materials used in potable drinking water systems are also currently regulated by a material toxicity standard called NSF-61. Both the recent lead reduction Iegislation and NSF-61 apply to the brass used in the products manufactured by NineSigma's client. Thus, Iiner materials and deposition processes are sought to manufacture faucets that meet the appropriate standards. POSSIBLE APPROACHES ° Materials of interest include polimers, rubbers, non-lead

metals, ceramics, and other thck coatlngs suilable for contact wlth potable water Approaches Not of Interest ° Dip coating, due to deposition of the liner on the external surface of

the spout Back to LaserLab Researches. Technology For Small Metall Particles Detecting in Silica (Quartz) Tubing Small and Fast Electric Water Heater Technology to Reduce Foaming in a Boiler Compact Boiler Design/Technology |

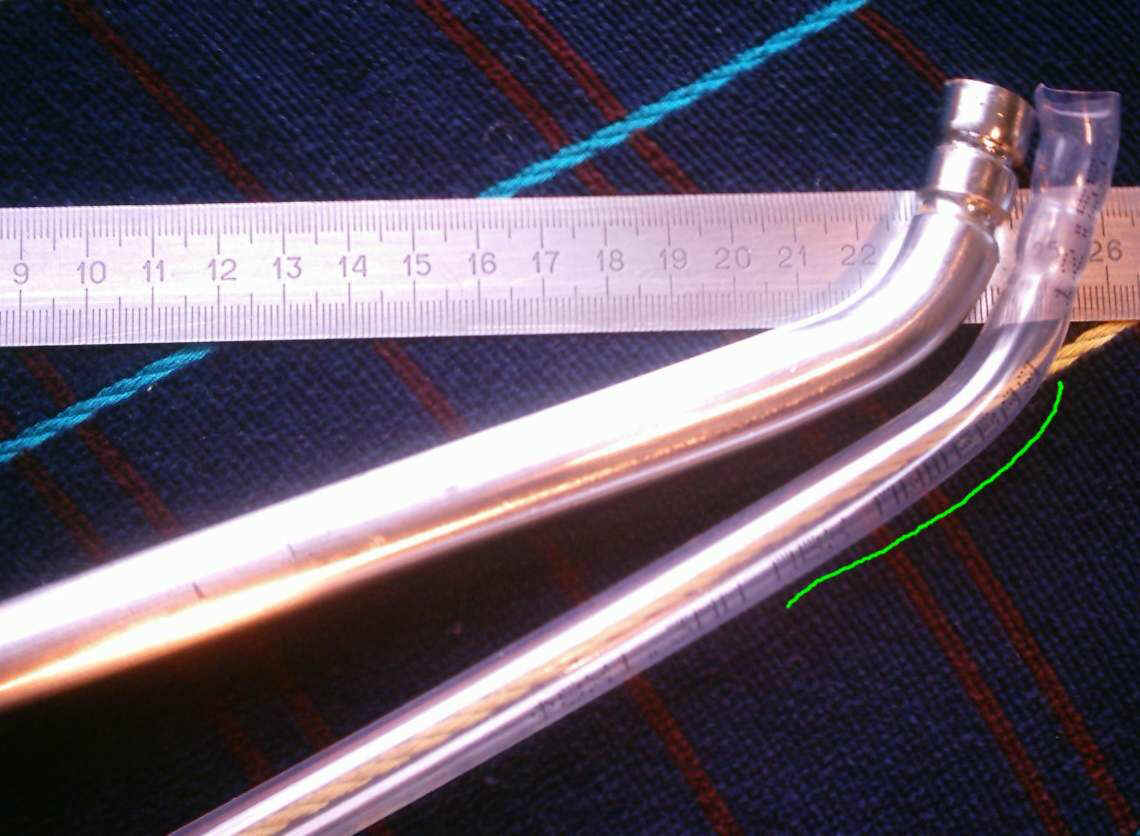

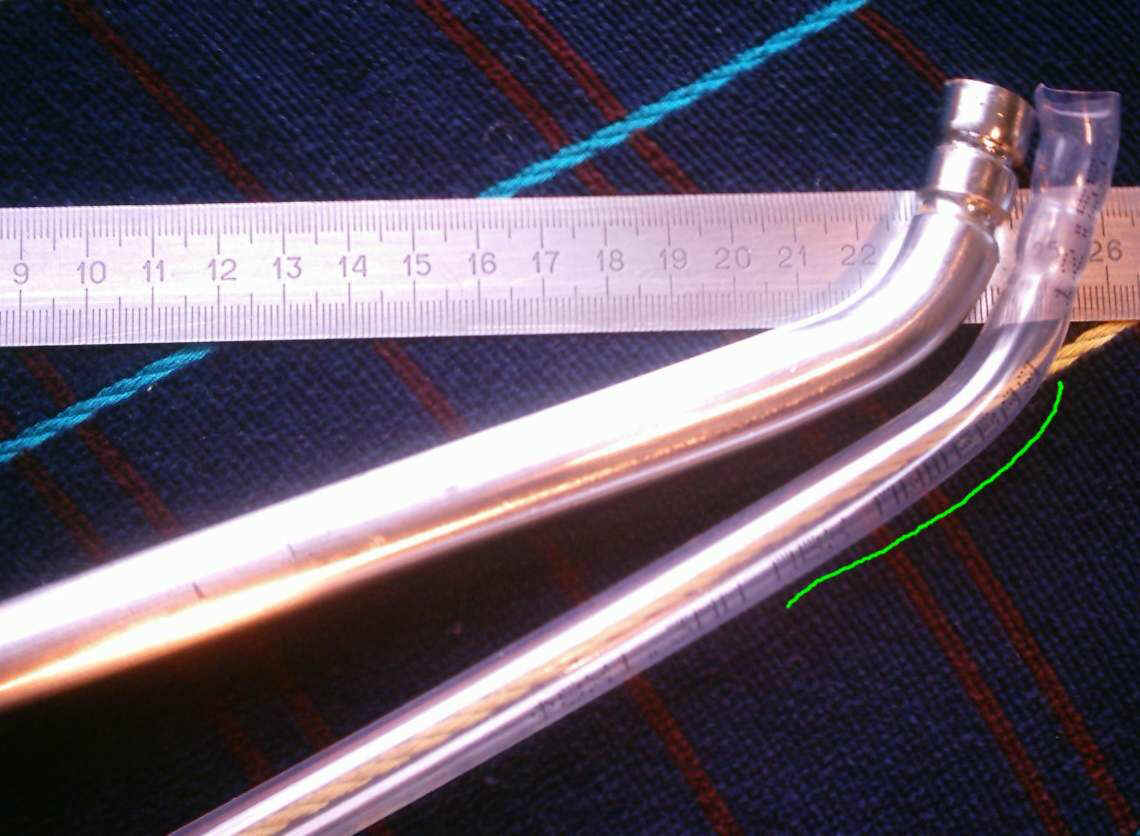

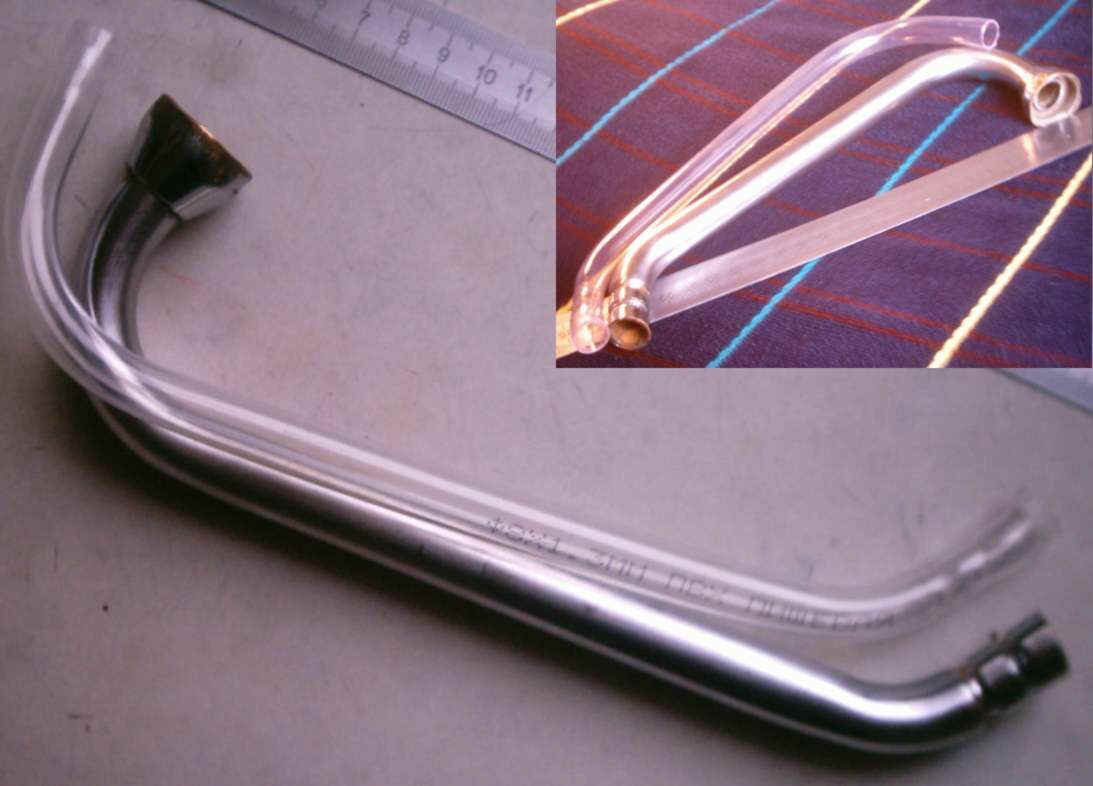

Achieved Faucet Spout Liner Produced by Tube Reforming I am a faculty memberwith a technology that should provide a solution, but requires further research and development to ready it for transfer to commercial use. Proposed Technical Approach To my mind the most effective and economical way of liners production for big variety of spouts is a ready made tubes reforming, unique or novel feature of method proposed is an utilization of spout itself as a mould. To check this idea in practice I took a ready made (of PVC destined for drinking/potable water, almost any thermoplastic can be used) tube of suitable diameter for a spout available (price - less then $0.15 per liner presented on the following photos). It took about 10 minutes to reform the tube with appliances available at home, after that it was taken off the spout for photographing. The first photo shows detailed view of parts with changing cross-section. Centimeter rule can be seen as background, inscription underlined by green means in Russian “PVC destined for drinking/potable”. The second photo represents general views of liner received along with its “spout-moulder”. Proposed Plan and Deliverables Of course, the process can be intesified with the use of equipment specialized and

automated. Devices needed: 2-3 temperature (10- Proposed Budget I believe that said equipment can cost less then 10 thousand dollars for productivity about 1liner per minute with one operator and it can be developed due to timeline and financials declaired. Although I work in NTU “KhPI”, in this proposal I act as a private person.

CONTACTS: Tel. +38 099 437 2436 (Viber, Telegram)

|

Last modified

29.06.22