Requested by NineSigma RFP #50562-1 - Technology to Reduce Foaming in a Boiler REQUEST FOR PROPOSAL DESCRIPTION Characteristics of successful technologies include the following: ° The proposed technology should enable water to be converted into steam in a boiler

without the formation of foam upon extended use, up to 1000 L of water ° The solution should be integrated and "ready-to-use" upon purchase of the consumer device (i.e., no additional action by the user should be required, such as adding an ingredient to the boiler chamber) BACKGROUND In boiler systems foam formation occurs as a result of accumulation of impurities which are present in the feed (i.e., tap) water. Liquid chemicals that suppress this foaming are well known in the industry. However, as far as we know, these chemicals are bulky and not suited for use in consumer applications. More concentrated liquids that are not bulky would be of interest. Therefore, new approaches to suppress the foam formation in boilers are needed and

which can Relevant specifications on the boiler system include the following: ° The boilers come in various volumes, ranging from 250 to 1000 mL POSSlBLE APPROACHES Technologies that are added to the feed or boiler water in order to suppress the foaming are of interest, including both chemicals and mechanical solutions. The solutions may use novel materials and innovative technologies that, by suppressing foam formation, reduce the carry over of water outside the boiler. APPROACHES NOT OF INTEREST Systems that require any other modifications of the existing boilers, the boiler

controls, or other parts are not of interest. Mesh systems (to break the foam) and

ultrasonic vibration to eliminate foam formation have already been explored and are not of

interest. Systems that suppress the foam formation based on the addition of liquid or

toxic chemicals are not of interest. Back to LaserLab Researches. Liner/Coating Technology for Faucet Spouts Small, Fast and Simple “Z/K” Electric Water Heater Compact Boiler Design/Technology Holographic seal defended from holographic copying Technology For Small Metall Particles Detecting in Silica (Quartz) Tubing Origin of life experiment enlightened by laser

Last modified 29.06.22 |

Achieved Technology to Reduce Foaming in a Boiler by FoamKiller Proposed Technical Approach An essence of proposed technical approach is in foam evaporation just after a boiler. It is possible by my FoamKiller (low-power foam evaporator, as it will be shown it can be placed in a few centimeters tube) as a result of structure simplification and the most possible elimination of any obstacles for heat generation and transfer. Consistent application of this approach resulted in a small, powerful and effective heater made with the use of materials and instruments that can be found in almost any home, the most expensive element of said heater is a power plug, very compact but able to heat 25ml of water to 94-97 Celsium degrees in 3-5seconds (this process is illustrated by video boiler.avi). This very principle applied to foam can effectively destroy it by evaporation. Although the principle was tested for very effective water boiling, nothing can prevent it from evaporating much less mass of foam – with evident from the above mentioned data fast heat transfer (much faster then simple heat conduction).

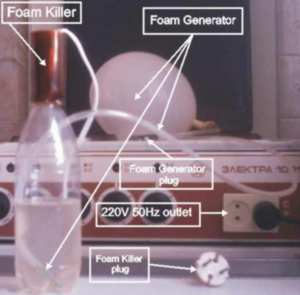

An increase of element sizes for foam evaporation can be made without power growth (rather with its decrease), this was proved by tests described below: measured watt consumption was not more then 100W – enough for evaporation of about 0.04g of foam per second. Photo of a tested device with some comments you can see above this text, the length of brown device case is 7cm, half-litre plastic bottle with water/kitchen detergent solution playing role of a foam suffering boiler. A movie FKiller.avi illustrates different regimes of FoamKiller work at real time scale. The heater turns itself off in water or foam absence (hence, there is no problem of overheating or excessive energy consumption without foam) – please note that power is already on when at the first second the foam generator (the white air balloon at the background) begins to work by its plug opening. Foam gets into device somewhere at 5-7th second, and at 9th a steam is already seen at the device exit. In order to show the effect of the device turning off, at 12th second the power plug is disconnected – and steam immediately disappears. Foam emerges over device’s upper end at 14th second, and at 16-17th power is turned on again resulting in foam transformation to steam in a few seconds. As far as I know, there where no publications concerning the heater discussed, so let us consider it as a trade secret.I believe that respected NineSigma’s client made good enough patent/literature search and analysis to find even traces of FoamKiller, so I hope it can be patented. Proposed Budget Unfortunately I have no business experience in this field outside former USSR, but I hope that declared ˆ100000 will be enough. Proposed conditions Joint development, licensing proposal. Your organization’s business model/proposed position on intellectual property developed during sponsored project and proposed materials I act as a private person in this development so I can propose the following: sponsor company hires me for the time of project development with remuneration correspondent to my education/experience and negotiable compensation in case of successful invention implementation. CONTACTS: Tel. +38 099 437 2436 (Viber, Telegram)

|