Requested byNineSigma RFP #50584-1 - Small and Fast Electric Water Heater

REQUEST FOR PROPOSAL DESCRIPTION NineSigma, representing a Fortune 500 Consumer Products Company seeks

ploposals for development of smaII, fast, eIectric water heaters.

Proposals for the heater system (including temperature sensors and fuses) are of The key challenge for this project is reducing the heater size by 50% and achieving high power density and heat transfer rates. Target specification include the following: -Supply heated water within 5 seconds of heater activation -Maximum voIume of the heater: 80 cm' (200 cm' max for the heater and pump system) -Maximum electrical power: 2500 W -Input water temperature: 10-30'C -Adjustable water flow rate: 3-6 ml/s -Operating water pressure: 1-10 bar absolute -Maximum flow resistance of the water heater 1bar BACKGROUND Water heaters have been widely applied in a variety of consumer devices. However, waiting times are long and their large size limits the product design freedom. The two important subprocesses in a water heater are the following: ° Generating heat ° Transferring the generated heat to the water Therefore, technologies are needed to improve at least one of these sub-processes to enable an electric water heater with small dimensions, and with a short time between activating the heater and the first supply of hot water. The maturity level of the chosen technology must enable mass production of the water heater after a maximum development time of one year. Due to confidentiality reasons, more detail about the end application for this project is not available at this time. However, a successful heater will be applied in one or more large volume consumer devices. POSSlBLE APPROACHES All flow-through heaters with high power density heaters are of great interest. The key challenge will be the aggressive size reduction and to improve heat transfer to achieve the rapid heating. Heating systems in which a large amount of water is first heated and then pumped cannot meet the requirements, and are therefore not of interest. In other words: ° Of interest: systems in which heating and pumping are carried out in parallel are of interest ° Not of interest: systems in which heating and pumping are carried out in series Back to LaserLab Researches. Other developments Liner/Coating Technology for Faucet Spouts Technology to Reduce Foaming in a Boiler, Compact Boiler Design/Technology Holographic seal defended from holographic copying Origin of life experiment enlightened by laser

|

Achieved Small, Fast and Simple “Z/K” Electric Water Heater

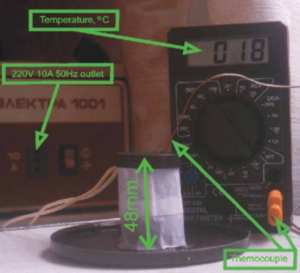

Proposed Technical Approach An essence of proposed technical approach is in a structure simplification and the most possible elimination of any obstacles for heat generation and transfer. Consistent application of this approach resulted in a powerful effective heater made with the use of materials and instruments that can be found in almost any home,the most expensive element of said heater is a power plug. After some improvements needed for power increase a heater sample was tested along with video clips shooting (attached). Specifications achieved with tested sample (initial water volume about 25ml) are as follows: Heating element volume – less the 5 (five) ml. Maximum heater power – 1,5-2kW (7-8A, 220V/50Hz), no principal obstacles for it’s increase by size/power scaling. Photo of tested device with some comments is attached as boiler.jpg. The heating element was placed in a plastic case from 35mm camera film. Case’s cap was provided with a hole (5mm diameter) for steam removal and for thermocouple introduction. Temperature can be measured by thermocouple connected to digital multimeter. Boiler.avi shows heating process at real time scale, it can be seen that power was turned on at 3-4th seconds and 96 Celsium degrees were achieved at 8th second. Steam and water splash can be seen along with device moving because of it’s vibration (brown base was attached underneath just to prevent boiler from jumping and turning-over). It takes 5-7 seconds for heating to 95-97Celsium degrees, this time varies from test to test due to thermocouple position change and substantial non-stationary nature of heating process. Although the heater turns itself off in water absence, residual heat results in plastic case deformations restricting a number of possible tests. As steam and water splash shows at Boiler.avi, a heater itself successfully acts as a pump. Taking into account that in water absence Z/K heater's power consumption is zero, proper heater cavity design with appropriate input valve\doser can avoid need in special pump. As far as I know, there where no publications concerning the boiler discussed, so let us consider it as trade secret. I believe that respected NineSigma’s client made good enough patent/literature search and analysis to find even traces of tested boiler, if they really existed, but declared boiler specifications show that this is not a case – so boiler proposed can be considered as new and patentable. Proposed Budget Unfortunately I have no business experience in this field outside former USSR, but I hope that declared $75000 will be enough. Proposed condition Joint development, licensing proposal Your organization’s business model/proposed position on intellectual property developed during sponsored project and proposed materials I act as a private person in this development so I can propose the following: sponsor company hires me for the time of project development with remuneration correspondent to my education/experience and negotiable compensation in case of successful invention implementation.

CONTACTS: Tel. +38 099 437 2436 (Viber, Telegram)

Technology For Small Metall Particles Detecting in Silica (Quartz) Tubing Composite Metal Oxide Particles Conveyor method of large containers leakage measurement

Last modified 26.06.22 |