Requested

by NineSigma RFP #50650-1 -

"Compact Boiler Design/Technology"

REQUEST FOR PROPOSAL DESCRIPTION

NineSigma,representing a global consumer products company is seeking proposals for ultra-compact

boilers that can supply dry or saturated steam in small mass produced portable

consumer devices. Solutions of interest include steam generation and control technology

assuring at least 1000 hours (non-continuous over possibly 10 years) of robust,

consistent, safe and reliable operation without the use of chemical treatment of

water for scale management. Complete systems are of primary interest, but new alternatives

to the boiler or heater sub-systems will be evaluated.

Characteristics of successful technologies include the following:

° Provides continuous steam of 30 g/min (approx. 1300-1400 W heat delivered)

from a 100-150 ml of water chamber

° Total volume (boiler chamber, heater, controller, temperature sensors, fuses)

less than 250 cm'

° Able to provide short-duration steam bursts (e.g., 5-6 g within 2 seconds and

10 g within 5 seconds)

° Complete product lifetime of 1000 L of standard "hard" water for 10

years and approx. 250,000 steam on/off cycles

° Safe and robust for consumer use (no corrosion-related failures, reliable power

system, etc.)

° Target cost (in high volumes) < $10 US

Additional specifications for the boiler system include the following:

° Shell: Stainless Steel of appropriate grade, or alternatives

° Operating Pressure: -4 bars (however, must survive safety testing at 20 bars)

° Mature production technologies for consistent, reliable boiler performance

for the 10 year lifetime

° Proven solution for avoiding foaming and water carry-over

° Control scheme for heating and pumping that delivers consistent steam

output— avoid steam stoppage / fluctuation during water feeding to the boiler

° Preferable that the system can be FDA approved

BACKGROUND

Current steam generating devices for appliances are generally bulky and are susceptible

to effects of scaling. The objective is to identify new compact approaches for a new

consumer device (quantities are expected to exceed 600,000 per year within a few years).

Compactness is enabled by a small-sized steam generating device (boiler),

but scaling and steaming performance become major challenges. For example, because of

scaling, there can be foaming of the water in the chamber or carry over, requiring a much

larger chamber to hold a smaller amount of water. Tradeoffs between external heaters and

immersion-style heaters are the following:

° For externaI heaters — A small boiler requires a small and

powerful heater combined with a control system and fuses. The heater is currently

difficult to make.

° For immersion-style heaters — The heaters can become

corroded over time due to impurities, especially chlorine. The level of impurities in the

water chamber increases over time.

Therefore, new approaches to generate steam in a compact volume are needed.

POSSlBLE APPROACHES

Technologies with shell type boilers with periodic water feed are of interest. Heating

may be with an external attached heater or immersion heater. Instantaneous (flash) boilers

may be considered, provided the requirements described above are met, and there is no

perceptible delay in steam start and stop upon activation and deactivation respectively.

The solutions may use novel materials and control schemes for the boiler, and

convenient and cheap methods to manage water carry-over due to foaming and scaling

effects.

APPROACHES NOT OF INTEREST

Solutions that need out-of-the-appliance descaling of feedwater and/or which require

frequent replacement or regeneration of water treatment chemicals are not of interest.

Back to LaserLab

Other developments

Liner/Coating Technology for Faucet Spouts

Small, Fast and Simple “Z/K” Electric

Water Heater

Technology to Reduce Foaming in a Boiler,

Holographic seal defended from holographic

copying

Technology For Small Metall Particles Detecting

in Silica (Quartz) Tubing

Composite Metal Oxide Particles

Conveyor method of large containers leakage measurement

Origin of life

experiment enlightened by laser

My social activity

Last

modified

26.06.22 |

Achieved

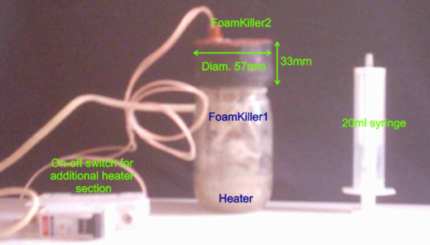

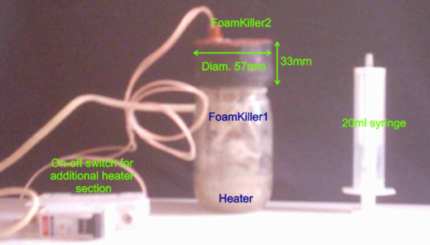

LazArt Boiler with FoamKiller.

Proposed Technical Approach is based on my earlier tested and working developments

– Boiler ( in a

response to “A

Fortune 500 Consumer Products Company seeks proposals for development of small, fast

electric water heaters” , still under consideration) and FoamKiller (to “A global consumer

products company is seeking proposals for technologies that can reduce or suppress the

formation of foam in a boiler that converts tap water into steam” , rejected by

NineSigma’s customer). Of course for target characteristics of current RFP

approaching they were redesigned as it is shown by photo below. 165ml capacity glass jar

from children nutrition serves as a water chamber. A two-section heater was placed at the

chamber’s bottom, metallic jar’s cap was used as a base for two stages

(FoamKiller1 and FoamKiller2) of foam evaporator. Taking into account FoamKiller2

dimensions shown at photo, we can state that total volume (boiler chamber, heater,

controller, temperature sensors, fuses) is less than 250ml. 2. All those elements are

based on the same principle, illustrated in action at above mentioned videos Boiler (targeted to achievement 95ºC at 4-5seconds) and FoamKiller (demonstrates as well total water-absence proofness of the

design: please note that from the very beginning of FoamKiller power is ON

– with no sad consequencies). The device in action can be seen at 40-17.avi (40ml of hot water were placed in the boiler chamber

and 17ml were evaporated during video shooting). Turning power on and off (the 2nd

and 24th seconds of film respectively) is indicated by image color changing

with additional lamp light. Real boiling begins at 6th second with ordered

steam burst (6-8s), the second one (17-20s) is better seen by steam going not only up

through FoamKiller2 output, but also down from jar cap. So during 18s boiling 17g were

evaporated. Projected power growth in bursts was about 4times, so if in regular regime

boiler productivity equals to X g per second, the “burst productivity” was 4Xg/s

and we have X about 17/33 or 0.5g/s for regular and 10g/5s for burst regime – just as

in RFP.

3. It should be noted that big (25A) “burst switch” shown on the photo and

used in video is not obligatory. Smart and reliable heater adaptive control can

successfully substitute the switch by, for example separate water feeding to different

“regular” and “burst” sections or even heaters (of course, with taking

into account other features of client’s system as a whole). This reason can be

illustrated by video 60-13glass.avi, where boiling of

60ml of water is shown, resulting in 60-13=47ml of water in a glass (of course in this

case – without FoamKiller - some water was splashed, so real productivity was not

13/4=3.25g/s, rather 2,5g/s as was estimated for “burst” mode).

4. It should be stressed that the heater shooted in

60-13glass.avi WAS POWERED DURING THE WHOLE FILM, from the very beginning – and

nevertheless it was handled (at least for 3s shown, in water absence!) with naked hand

– and in four seconds (10-14th) it produced and effectively transmitted to

water some kWs and immediately diminished the power (15th s and later) in water

absence.

5. To my mind (taking into account its physical essence) – it is the most

effective and reliable water heater concept from any possible one, because in addition to

already illustrated virtues, it possess inexpensive design (all materials spent in

experiments discussed, totally cost less than $3-4), almost insensitive to scale (it

precipitates or deposits itself at the bottom or at chamber walls (this is why in the

videos presented initially transparent glass jar looks opaque), and I never saw it at

heater surfaces, although observed a man using self-made heater of this kind in tea

preparation for at least two years – with just the same water source - Kharkiv city

water conduit). 6. Demonstrated heater sensibility to water presence/absence (by consumed

power level change) can produce reliable control signals for feeding water valve and opens

the way to steam production stabilization and water carry-over avoiding. Obviously this

part can be properly developed only with full understanding of the whole client’s

device destination and structure, because, as possible examples, an iron, coffee machine

or sauna – are too different. 7. Simplicity results in reliability: if there

is nothing to be damaged, it will not be damaged. Even home-made examples tested in

experiments described survived about hundred on-off cycles, more than dozen video clips of

“jar-based” model are available from one shooting session; even in Tic-Tac (from

Ferrero) sweets box with inner volume jf 25ml a heater boiling 20ml of water in 6s can be

placed with FoamKiller in the second box ( TicTac.avi,

power on since 5th s can be seen ).

Proposed Plan and Deliverables

I act as a private person in this development so I can propose the following: client

company hires me for the time of project development with remuneration correspondent to my

education/experience and negotiable compensation in case of successful invention

implementation

Proposed Budget

Unfortunately I have no business experience in this field outside former USSR, but I

hope that declared Euro100000 will be enough.

CONTACTS:

Tel. +38 099 437 2436

(Viber, Telegram)

E-mail

|