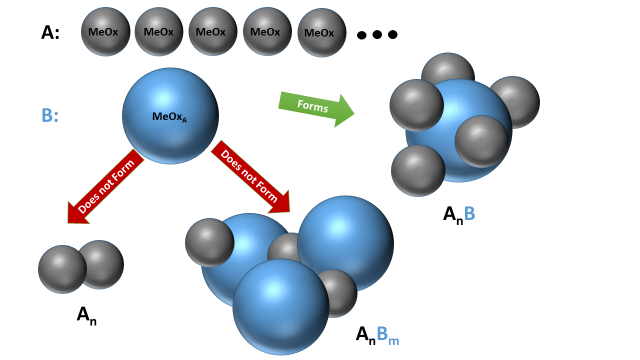

Requested by NineSigma RFP #3289901 Composite Metal Oxide ParticlesREQUEST FOR PROPOSAL DESCRIPTION NineSigma, representing a multi-billion dollar chemical manufacturing company, invites proposals for developing a technology to prepare discrete composite metal oxide microparticles composed of attachments of individual metal oxide nanoparticles to a larger metal oxide microparticle in an efficient and effective manner. BACKGROUND Both

microparticles (200-400 nm) and nanoparticles (50-200 nm in cross section)

are routinely prepared with silica, alumina, or other metal oxides

incorporating similar surface structures. Our client is seeking particles

featuring a hybrid structure that is composed of a plurality of metal oxide

nanoparticles attached to a microparticle as illustrated above. Note that

the cartoons in this RFP are meant to illustrate the general structural

representation desired – the shapes are not necessarily spherical. They are

looking for an efficient process to generate such structures that would be

applicable in large quantities in a high-volume manufacturing facility. The

process should provide a means of robust deposition of metal oxide

nanoparticles onto larger metal oxide microparticles resulting in stable

dispersions in water or organic solvents. Key Success Criteria The successful technology will: POSSlBLE APPROACHES Possible approaches might include, but

are not limited to:

Not of interest: The following approaches are not of

interest:

Back to LaserLab Researches. Other developments Liner/Coating Technology for Faucet Spouts Technology to Reduce Foaming in a Boiler, Compact Boiler Design/Technology Holographic seal defended from holographic copying Technology For Small Metall Particles Detecting in Silica (Quartz) Tubing Origin of life experiment enlightened by laser

|

Proposed Composite Metal Oxide Particles Proposed Technical Approach

This respond is based on the methode filed 2012-06-26 07:39:19 at http://www.scireg.org/rus/files/file/455 non-confidentially described as "A method nanoparticles production, in which said nanoparticles are grown by combining in a suitable atmosphere of calibrated drops pairs produced from two different solutions containing the required components, as well as several kinds of devices to implement the method mentioned by continuous generation and two by two association of large (up to a billion or more pairs per second) drops pairs from the initial solutions, and to build additional layers on the nanoparticles along with the collection of the latter" and illustrated by the following picture:

The method is based on

strictly one-with-one droplets merger (due to specific physical mechanism,

the essence of which may be disclosed after NDA conclusion) of two different

colloidal solutions containing (in the required proportions) wanted micro-

and nano-particles. The solvents they may be the same or different (for

percolation desired reaction association), they also may contain (possibly)

the additives required(such as, for example, an organic glue solidifying

with solvent evaporation). Proposed Budget $150000 - about 2/3 for equippment and 1/3 - salary for 2-3 persons Proposal Team Experience Author’s CV is here , Holographic seal defended from holographic copying, some other responses to NineSigma RFPs: Small and Fast Electric Water Heater, Technology to Reduce Foaming in a Boiler, Compact Boiler Design/Technology, Faucet Liner.

CONTACTS: Tel. +38 099 437 2436 (Viber, Telegram)

Last modified 26.06.22 |