The copy of users.kpi.kharkov.ua/LaserLab/leakage.html (existed up to Sept. 2021), with modified CONTACTS

SO,

Requested byNineSigma RFP #50584-1 - Small and Fast Electric Water Heater

REQUEST FOR PROPOSAL DESCRIPTION NineSigma, representing a Fortune 100 Responsive proposals will provide supporting BACKGROUND

Our client manufactures specialty components in

POSSlBLE APPROACHES All approaches are of interest. Not of interest: Based on our clients’ experience with He

Back to LaserLab Researches. Other developments Liner/Coating Technology for Faucet Spouts Technology to Reduce Foaming in a Boiler, Compact Boiler Design/Technology Holographic seal defended from holographic copying Technology For Small Metall Particles Detecting in Silica (Quartz) Tubing Origin of life experiment enlightened by laser

|

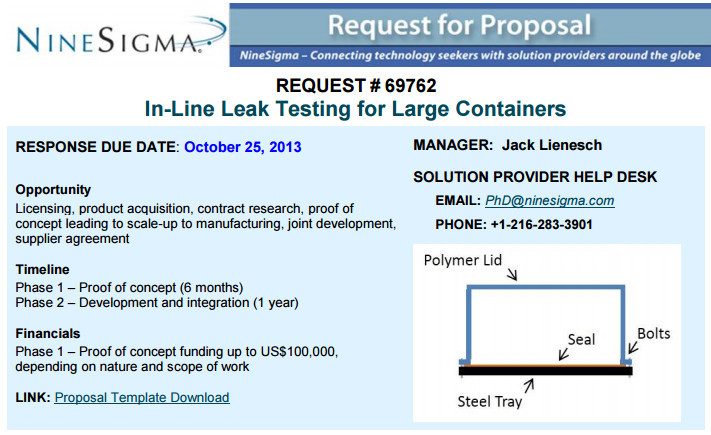

Proposed Conveyor method of large containers leakage measurement Proposed Technical Approach The method proposed does not require helium, vacuum, a mass analyzer or the use of harmful, radioactive or exotic materials and equipment. Calculations based on general physical laws (available in the patent application) show that in required by client 5 minutes (supposedly one of them - for preparation, three - for the measurement actually and the last one - to replace the container) the method will provide a possibility to measure the required 2ml/30 min leakage with an accuracy about 5-10 % at the expense of increasing the sensitivity at least in 55 times. The latter value is limited only by the maximum allowable excessive pressure for the contents of containers discussed and was calculated for the apparent (from the problem formulation) magnitude of 1 m of water column or 0.1atm. Increase in the allowable pressure will increase the sensitivity of the method proportionally and will reduce the measurement time or increase its accuracy. To improve the reliability two types of measurements are offered in parallel use: - more direct one which does not require calibration when changing the design of the container , but more difficult in automation, - more indirect but easier automatable. Both types of measurements are not related to the flow of water into the container. All things pertaining to this equipment, materials and communications for integration into an existing line can be found in any modern manufacturing capable to produce containers discussed (of course , it may take a few square meters of floor) . Requirements for operator qualification are minimal. It is possible that the tests will show a real opportunity to dwell the problem with only one of the two sub-methods mentioned. Patent pending, after NDA conclusion or priority date registration in about a week needed for application translation into English a description of the invention can be represented. A joint further development agreement seems to be the best promising way. The last version of the proposed method reduces the measurement of tightness in 0-2ml/30min ( with allowable excessive pressure for the contents of containers at 1 bar ) to the volume of the effluent from the test stand water measurement in the range 0-110ml during 5min test. Proposed Budget The costs of establishing and testing of the measuring system are highly dependent on the design of the containers themselves and the conveyor line that held their filling and sealing, but client’s proposal $100000 will be well enough. The last patent-pending option could need for testing 1-2 months (after the complete information about the required characteristics of the containers) and the following expenses: Materials - $1000 Equipment - $3000 Salary - $12000 overhead costs, travel expenses, taxes, and so forth - $8000 premium on success $25000 Proposal Team Experience Author’s CV is here , Holographic seal defended from holographic copying, some other responses to NineSigma RFPs: Small and Fast Electric Water Heater, Technology to Reduce Foaming in a Boiler, Compact Boiler Design/Technology, Faucet Liner, Composite Metal Oxide Particles

CONTACTS: Tel. +38 099 437 2436 (Viber, Telegram)

Last modified 26.06.22 |